· Liu JunLiang · 产品 · 需要4 分钟阅读

Unveiling the Float Flow Meter: A Comprehensive Guide to Its Applications and Benefits

Explore the intricacies of the float flow meter, an indispensable tool for accurate flow measurement in various sectors. This comprehensive guide covers its unique features, technical specifications, and its role in enhancing efficiency in water management, environmental protection, and industrial processes. Discover why this cost-effective solution is gaining popularity in the field of fluid dynamics.

A float flowmeter is an instrument that measures flow based on the principle of a float rising in a fluid. It is widely used in fields such as water conservancy engineering, environmental monitoring and industrial production. It works well with the design of simple structure, low cost, and easy installation and maintenance.

Product Characteristics

The technical parameters of the device are as follows:

- Specialized for float-based flow measurement systems

- 4-beam flow measurement

- Hierarchical flow velocity measurements, more adaptable to the flow velocity distribution in a wide basin.

- Hierarchical flow velocity and direction measurements, to understand the flow trend of the water body.

- Built-in temperature sensor, automatic calibration of the speed of sound.

- Built-in photovoltaic charging system to meet the requirements of field work.

- Measurement data can be transmitted to the server wirelessly without on-site wiring.

- Compatibility with a variety of wireless communication methods

Applicable cases

The application scenarios encompass the following major aspects:Water Conservancy Project Management,Environmental Protection and Industrial Generation Practices.

Water Conservancy Project Management

River flow monitoring:

The floating flow meters monitor the flow changes of water flow of the rivers chuannels in real time. This is of great significance for water resource management, flood prevention, early warning of danger, and water conservancy project planning. By suppling accurate measure data of the river flow, water resources can be rationally allocated, systems can ensure the safe operation of water conservancy facilities. Management of reservoirs operation:

By monitoring the in and out flow of reservoirs with the accurate data from the floating flow meters, the reservoir managers easily handle the water storage situation in the reservoir, rationalize the water resources layout, and improve the operational efficiency of the reservoir. Flow control in irrigation system:

The float flow meters can be used to measure the flow rate of irrigation canals to achieve precise irrigation. By adjusting the flow, farmers can improve the utilization efficiency of water resources, reduce wastage, with fulfillment of water needs of crops.

Environmental Protection

River ecological monitoring:

The floating flow meter can accurately measure the flow change of the river and provide data support for ecological environment assessment. By monitoring changes in flow, we can know the ecosystem health of the river, assess the impact of water pollution on the ecological environment. Flow Monitoring in Wastewater Treatment Plants:

In wastewater treatment plants, float flow meters can be used to monitor the flow of incoming and outgoing water to ensure the stable operation of the wastewater treatment process. The accurate flow data can help sewage treatment plants optimize the treatment processing, improve treatment efficiency and reduce operating costs. Groundwater Monitoring:

The floating flow meters can be used to measure changes in groundwater flow. This is important for learn the dynamics of groundwater and assessing the sustainability of groundwater resources.

Industrial Generation Practices

Chemical industry:

In chemical production, many processes require precise control of fluid flow. Float flow meters can be used in chemical pipelines, reactors and other equipment to achieve accurate data, which helps improve the stability of production and quality control , and reduce wastes and costs. Petroleum industry:

Flow measurement is critical in the extraction, transportation and processing of petroleum. Float flow meters can be used to measure the flow in oil pipelines, tanks and other equipment to provide accurate data for oil production and management. At the same time, the float type flow meter can also adapt to the complex working environment of the petroleum industry, with high reliability and stability. Food and beverage industry:

In the food and beverage production process, the need for accurate control of the flow of various liquids. Float type flowmeter can be applied to the pipeline and storage tank in the food and beverage production line.

Technical Parameters

| Name | Vlue |

|---|---|

| Product Model | FUC660-2M-U |

| Sound Path | Planar Array 4-Beam |

| Sound Beam Spreading Angle | 1.4° |

| Maximum Outgoing Call Rate | 20 calls/s |

| Measurement Range (Water Depth) | 0.06~25m |

| Blind Zone | 0.03m |

| Unit Layers | Maximum 256 layers |

| Unit layer Size | 0.15m~4m (Dynamically Adjustable) |

| Measurement accuracy | ±0.5%±1.0mm/s |

| Flow rate resolution | 0.001m/s |

| Flow rate Measurement Range | ±10m/s |

| Temperature Measurement Range | -25°C~75°C |

| Measurement Interval | 1-60min Adjustable |

| Data output | Flow Rate per Laye+ Average Rate |

| Operating Temperature | -10°C~60°C |

| Data Output | Layer Flow Rate, Average Flow Rate |

| Storage Temperature | -20°C~70°C |

| Waterproof Rates | IP68 |

| Power supply | Built-in lithium battery, photovoltaic charging board |

| Three-dimensional Compass Meter (optional) | North ±2% leanward , sideways ±0.5° |

| Compass Meterr Accuracy | ±0.5° |

| Material of Sensor | POM |

| Power Consumption | <4.0W |

| Communication Protocols | 4G |

| Communication Protocol | 4G/NB-loT/LORA |

| Sensor Size | 360*Ф158mm |

| Weight in Water | 0.85Kg |

| Reliability MTBF | >25000h |

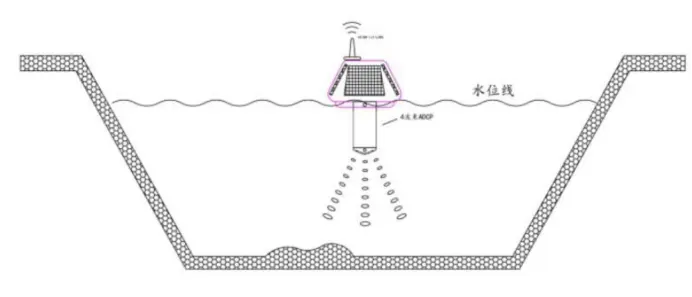

Schematic diagram of installation

The installation method is as shown in the figure:

Conclusion

The float-type flow meter, with its simplicity, affordable costs, ease of maintenance, has a wide range of applications in industrial and environmental monitoring fields. Although its accuracy will be slightly affected by the fluid viscosity, it remains a good choice for an effective flow measurement tool in appropriate application scenarios.